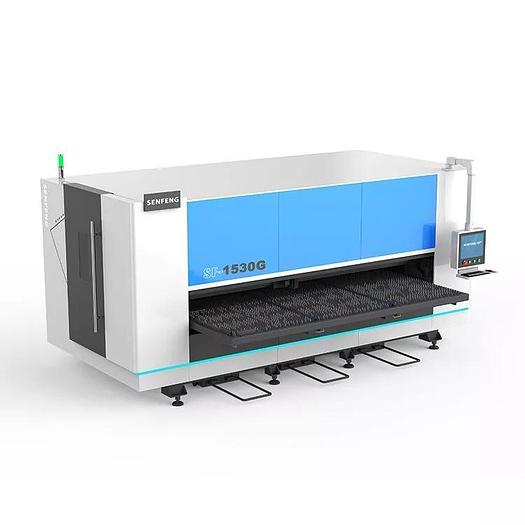

SF1530G-Fiber Laser Cutter for Metal Sheet with Single Table – 5’ x 10′

SF1530G-Fiber Laser Cutter for Metal Sheet with Single Table – 5’ x 10′

Contact us for price

Location:New Hope, MN

Description

SF1530G

-3,000w

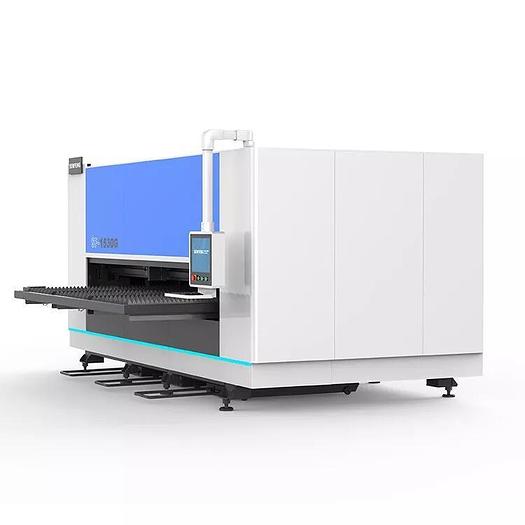

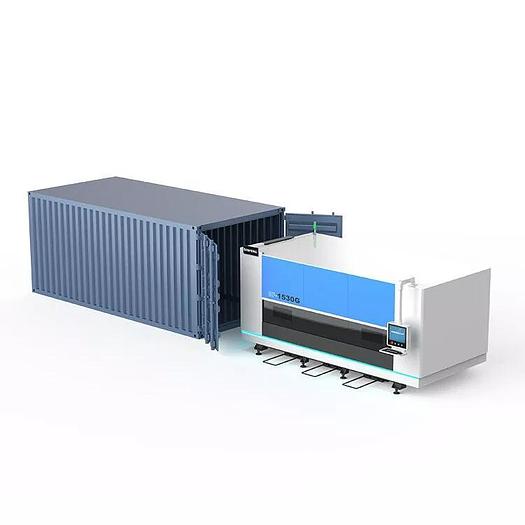

SF1530G Fiber Laser Cutter for Metal Sheet with Single Table – 5’ x 10′ Introduction SF1530G is a single table fiber laser cutter machine. The fiber laser power ranges from 1.5kw-3kw. The SF1530G has a small footprint and low cost. The fully enclosed machine and the baffled dust removal system help reduce dust and laser emissions. The pull-out platform makes for easier loading and unloading materials. This fiber laser cutter has passed CE/FDA /ETL certifications, which is in line with European and American standards. This machine requires 208v @ 200a 3ph / 480v @ 100a 3ph electrical input. SF1530G-Technical Parameters Cutting Material and Thickness Chart Advantages of Fiber Laser Cutter Fast Speed The cut speed can reach 32.8’/min when cutting light gauge sheet metal, and the speed of thin plate cutting is much faster than old plasma-cutting technology. 2. High Quality and Precision After cuts are made using the fiber laser, the cutting surface can be directly welded on without prep-grinding. Minimal surface deformation and roughness value is low, keeping the accuracy is consistent. Fiber laser cutting can accurately complete complex cutting with superior edge-quality. Our Fiber Laser cutter can create parts with precision tolerances in a fast, clean, and effective way with minimal corrections from the operator. 3. Costs Maintenance costs are low, and cost-effective in cutting light gauge sheets. Advanced software and narrow cuts allow the parts to be closely nested, thereby maximizing yield and reducing overall material waste. SF1530G Main Configuration Honeycomb Carbon Structural Steel Welding Bed The Machined-Bed is constructed of high-quality steel plate and tube. After welding, it undergoes stress relief annealing, a secondary aging treatment, and precision machining on a CNC Planomiller. This process ensures that the bed has sufficient structural stability, shock resistance and no deformation.2. Surrounding Vacuum Dust Removal System This position shows how air flow automatically opens and closes the air outlet to direct exhaust into a provided Dust Collector. 3. Pull-out Platform The 31.49″ worktable can be pulled out by hand and operators can use sheet lifters and material handling equipment to load and unload materials repeatedly.4. Packing Save freight cost. Save installation time. Entire machine can fit into a 20′ – container.

Specifications

| Model | SF1530G |

| Condition | New |

| Working area l x w | 118.11″ x 59.05″ |

| Laser power | 1.5KW / 3KW |

| X/y axis positioning accuracy | ±0.05mm |

| X/y axis repeated positioning accuracy | ±0.02mm |

| Maximum velocity of movement | 262’/min |

| Maximum acceleration | 0.8G |