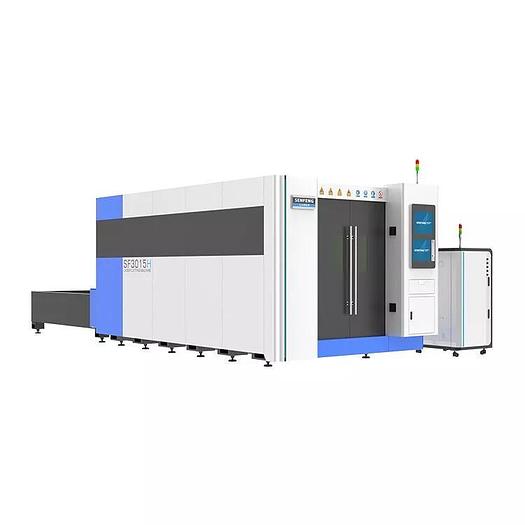

SF3015H4-High Power Fiber Laser Cutter-Fourth Generation

SF3015H4-High Power Fiber Laser Cutter-Fourth Generation

Contact us for price

Location:Fridley, MN

Description

SF3015H4

-12,000w

-20,000w

SF3015H4-High Power Fiber Laser Cutter-Fourth Generation Introduction The 4th generation SF3015H4 high power fiber laser cutter is mainly designed for high power : 12KW to 20KW, it comes with a full enclosure, preventing laser radiation and protecting the operators safety, reducing dust and Laser emissions; and it is also with auto-exchangeable platforms, which can save the materials loading time and improve processing efficiency. This loading platform only takes 20 seconds to complete the exchange. The SF3015H4 high power laser cutter has passed CE/FDA /ETL certifications, which is in line with European and American standards. This machine requires 208v @ 200a 3ph / 480v @ 100a 3ph electrical input. SF3015H4-Fiber Laser-Fourth Generation-Technical Parameters Cutting Material and Thickness Chart SF3015H4-Fourth Generation-Main Configuration 1. Heavy-duty thermally isolated hollow bed The heavy-duty thermally isolated hollow bed is welded with high-quality steel plates and tubes. After; welding, it undergoes an annealing process, secondary aging treatment, and machined using a CNC gantry-mill to ensure that the bed has sufficient structural stability and is able to be shock resistance. There is enough air-to-air flow inside the bed to transfer radiant heat, preventing heat generated by cutting from transferring to the bed and affecting the processing accuracy.2. Surrounding spiral negative pressure dust removal Surrounding spiral negative pressure dust removal system, and the baffled exhaust inlets are directed into a supplied dust collector. 3. Graphite copper protection The thermal conductivity of graphite-copper is effective in preventing the machine bed from being deformed by continued usage and promotes machine longevity.4. Strong Aviation Aluminum Beam The use of aviation-grade high-strength aluminum alloy beams, light weight, low inertia; built-in triangular reinforced structure, strong rigidity, good shock absorption; rough machining after annealing to eliminate internal stress, and machined after secondary vibration aging treatment to ensure Improve the overall strength and stability of the beam.

Specifications

| Manufacturer | Senfeng |

| Model | SF3015H/SF4020H/SF6020H/SF6025H/SF8025H/SF12025H |

| Year | 2023 |

| Condition | New |

| Work area | 120″x60″ /159.44″x79.92″ /238.18″x79.92″ /238.18″x99.60″ /316.92″x99.60″ /474.40″x99.60″ |

| Power | 12KW / 20KW |

| Positioning accuracy | ±0.05mm |

| Repeated positioning | ±0.02mm |

| Maximum speed | 590.55’/min |

| Maximum acceleration | 2.0G |

| Table maximum load | 3,080 lbs |

| Outline size | 350.78″ x 110.82″ x 99.01″ |