SF6020T-Professional Tube Laser Cutting Machine

SF6020T-Professional Tube Laser Cutting Machine

Contact us for price

Location:New Hope, MN

Description

SF6020T

-3,000w

-4,000w

-6,000w

OPTIONAL

-Full Auto Loader

-Unloader

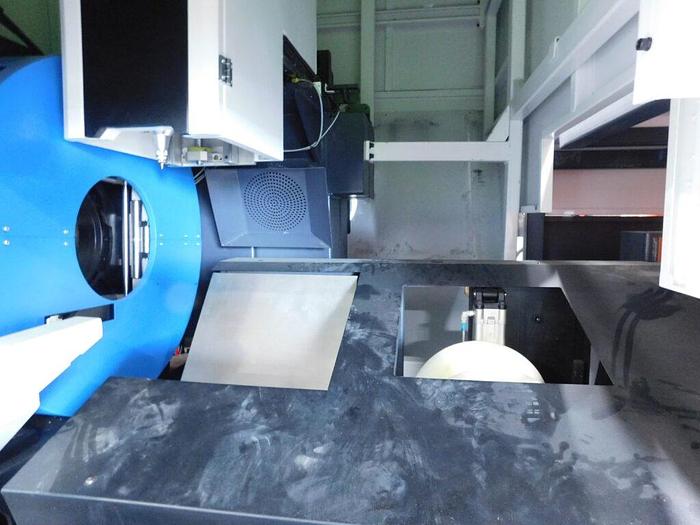

SF6020T-Professional Tube Laser Cutting Machine Introduction SF6020T Automatic metal tube laser cutter is used for cutting; round tube, square tube, rectangular tube and other metal tubes. Can cut round pipe with diameters from 0.7" up to 8.6 ” and square tube with side length up to 5.9 “ The SF6020T tube laser cutter machines are equipped with a MAX fiber laser source, from 3KW to 6KW Laser Power. This machine requires 208v @ 200a 3ph / 480v @ 100a 3ph electrical input. SF6020T-Technical Parameters SF6020T Professional Pipe Laser Cutting Machine Advantages Automatic Loading Through the numerical control operating system; the loading and unloading, automatic collection of finished products and materials, saving labor costs and consistent cutting efficiency. 2. Floating Support The unique V-shaped positioner and parallel-follower support compensates for “drooping” and “swing” of long workpieces to ensure the entire tube cutting is cut with accuracy. 3. Honeycomb Carbon Structure Our machinery bases under go a high temperature annealing treatment, using precision welding process, promoting high strength and stability. SF6020T-Applications Laser pipe cutter is applied in locomotive, automotive, construction, agricultural, forestry machinery, electrical manufacturing, elevator manufacturing, home appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware, decorative advertising, laser processing services and other machinery manufacturing industries. Ideal for cutting; round pipe, square tube, U-Shaped tube, rectangular tube and other different shapes of tube/pipe.

Specifications

| Model | SF6020T |

| Condition | New |

| Pipe processing range | 20’L x 0.7″ ~8.66″Diameter |

| Laser power | 3KW/4KW/6KW |

| Maximum speed | 328’/min |

| Maximum rotational speed | 100rpm |

| X/y axis positioning accuracy | ±0.05mm |

| X/y axis repeated positioning accuracy | ±0.03mm |